DESIGN OF FLAT AND V BELT DRIVES

DESIGN PROCEDURE OF FLAT BELT DRIVE STEP 7 :; Coefficient of friction between pulley &belt using Barths formula 0.712 2.542+v uu =0.54- < below eqn 14.3(d)/page290 Or using Table 14.2(b)/page 305 If material of belt different select 4 from table 14.2(a)/page305 STEP 8: Determine length of belt (open/cross) refer eqn 14.2(b),14.2(c)/page 290

Learn MoreDESIGN PROCEDURE FOR V BELT DRIVE-converted.pdf - Course Hero

DESIGN PROCEDURE FOR V BELT DRIVE STEP 1: MATERIAL SELECTION BELT Rubberized Fabric PULLEY Cast Iron STEP 2: Select suitable Belt cross-section based on power transmitted. (DDB7.58) STEP 3: Calculate diameter of smaller & larger pulley. 𝑖 = 𝑁 𝑛 = 𝐷 𝑑 Nd = nD Where, D- Larger pulley diameter, N-Smaller pulley speed d-Smaller

Learn Morecrusher spares indonesia | v-belt design procedure

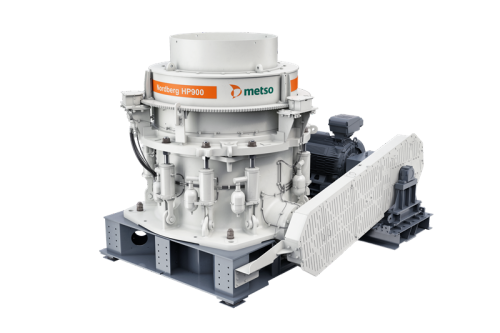

Process Technology. Products. Modular Systems. Turnkey Systems. Parts & Services. Projects. WELCOME TO POWERSCREEN INDONESIA Powerscreen is an expert in the design and manufacture of mobile crushing equipment, mobile screening equipment and mobile washing equipment. crusher plant spares eccentric bushing v-belt pulley near me hp200

Learn MoreV-Belt Design Manual - All World Machinery

Driving Motor: 5 Hp @ 900 RPM, Outer Datum Diameter 3.0" DriveN Sheave: 250 RPM Center Distance: 32" Design HP = Transmission HP x Service Factor Design HP = 5 X 1.2 (from Table

Learn MorePDF proper belt tensioning - BestorqPDF

The highest quality belts still lose nearly 50% of installed tension, while lower quality belts lose over 70% of installed tension. You cannot "feel" the correct tension on a V-Belt. On a test given to over 200 experienced maintenance personnel, only 1% tensioned a belt correctly using the "feel" method.

Learn MoreDesign Procedure For V Belt [mwl1gxgzm9lj]

Design procedure for v- belt Step:1 Selection of belt PSG design data book (page number 7.58) select CSA of belt depend up on power transmitted Step:2 Selection of pulley Select small

Learn MoreV_belt design procedure.pdf - Procedure for designing

View V_belt design procedure.pdf from MECHANICAL 1 at Banha University. Procedure for designing V-Belt drive based on DIN Get service factor C2 from Table A-2 Select Type of Belt

Learn MoreDesign of V - Belt Drives Notes - Mechanical Engineering

A typical V-belt section is shown in Fig.13.3.1. The geometrical features of the belt section are indicated in the figure. The pitch line, which is also marked

Learn MoreV - Belts" - Design of Machine Element - SlideShare

Designation of V-Belts, • V-belts are designed by the symbol of cross section with the inside length of the belt in mm. • The relation between pitch length and inside length of V-belts is written as follow: Pitch Length = Inside length + correction (L) (Li) (δ) • For example, E 3333 is having C-section belt and 3333 mm inside length. 8.

Learn Moretiming belt, V-Belt and Flat Belt Design and Engineering Formulas

V-belts need larger pulleys for their thicker cross-section than flat belts. For high-power requirements, two or more V-belts can be joined side-by-side in an arrangement called a multi-V, running on matching multi-groove sheaves. This is known as a multiple-V-belt drive (or sometimes a "classical V-belt drive").

Learn MoreDrive design (V-Belt

Belt drives engineering manual. 131. CALCULA. TION www.sitspa.com. Design. To obtain the full advantages of a SIT belt, it is necessary that the drive be

Learn More

Leave A Reply