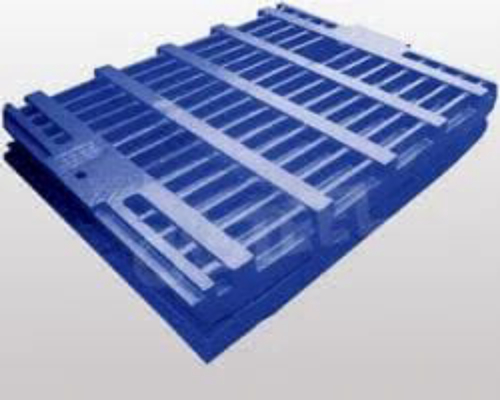

grinding mill liners

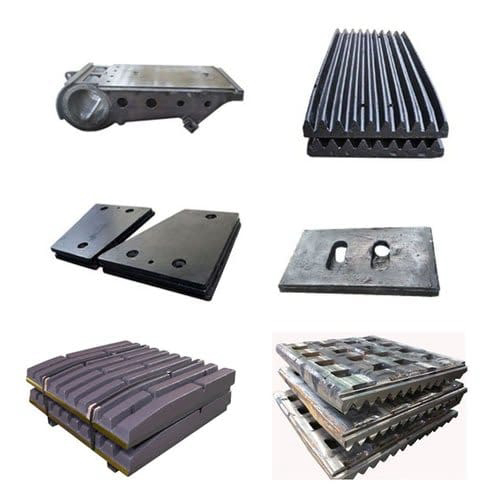

GRINDING MILL LINERS · 1. Abrasion Resistant (AR) Steel: · 2. Ultra High Molecular weight (UHMW) Polyethylene Plastics: · 3. Urethane: · 4. Ceramic: · 5. Ceramic

Learn MoreCutting-edge Mill Liners

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials. But even if they all do

Learn MoreTypes of ball mill liners

For instance, rubber liners are topped sealers. Using liners or sealers can ensure continuous production without any fear of leakage. One of the purposes of the liners is to absorb the impact of the milling movement. With the presence of the liners, it decreases the shock, thus causes less or no damage to your ball mill.

Learn More7 Types of Grinding Mill Liner Materials - Industrial Mechanical

The design of grinding mill liners depends on the type of material that is used for making, as well as its implementation. Read and know about the wide range of materials that are used in the construction of mill liners.

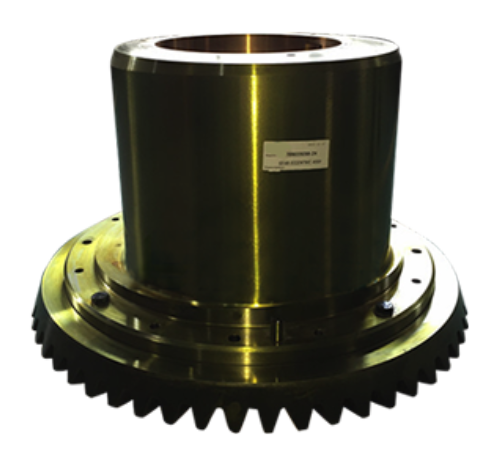

Learn MoreThe Selection and Design of Mill Liners - MillTraj

An overview is given of the principal types and materials of construction of mill liners. Examples of good and bad liner design are given, followed by a

Learn MoreBall Mill Liners manufacturers & suppliers

Citic Mill Body Lining Plate For Protecting Body Shell Product Description CITIC IC mill body lining Mill Liners:Ball Mill Liners, SAG/AG Mill

Learn MoreTypes of ball mill liners - Consuol Mining Machinery

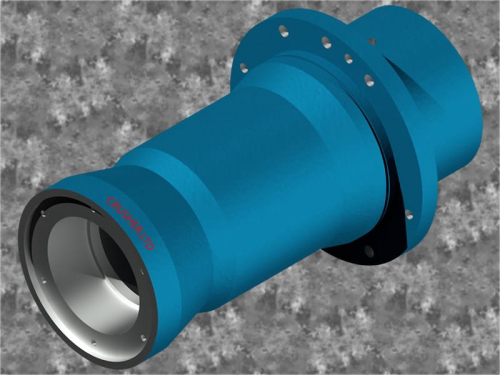

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates. The MultoMet range utilises Hardox 500 wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance

Learn MoreMill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

The rubber linings produced by AGICO CEMENT can generally be divided into ball mill rubber linings, rod mill rubber linings, tube mill rubber linings, AG mill rubber linings, and ceramic mill rubber linings. The rubber lining can meet the technological requirements of one-stage rough grinding and two-stage fine grinding.

Learn MoreMill liner wear and performance monitoring - Outotec

Outotec's wear management solutions extend liner life cycles, optimize throughput and uptime and empower better decision making with accurate wear reports and thorough analysis and wear forecasts. Furthermore, knowing the current and historical wear rates, wear behavior, and performance of the mill is a prerequisite for liner optimization.

Learn MoreMining - Polycorp

Proudly manufactured in Canada, Polycorp has supplied mill liner solutions numerous patents for different types of liners and mill discharge systems.

Learn MoreTypes Of Cement Mill Liners

Rubber shell liner backing should be used with all cast type rod mills shell liners. If the shell liners are of the step type, they should be assembled with the thin portion, or toe, as the leading edge with respect to rotation of the mill. Lorain liners for the shell are provided with special round head bolts, with a waterproof washer and nut

Learn More

Leave A Reply