Roll crushers - SlideShare

4. ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing. Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect

Learn MoreMarcy ® Double Roll Crusher - Gilson Company

These crushers are constructed of fabricated steel and equipped with a fabricated steel drive guide for operator safety. They have a tilt-design feed hopper,

Learn MoreDouble Roll Crushers | Moore Watson Ltd

Double roll crusher Roll Crusher. Consultancy, design and manufacture of mining, mineral processing and recycling equipment. E: [email protected].

Learn MoreDouble Roll Crusher Machine Design - [PDF Document

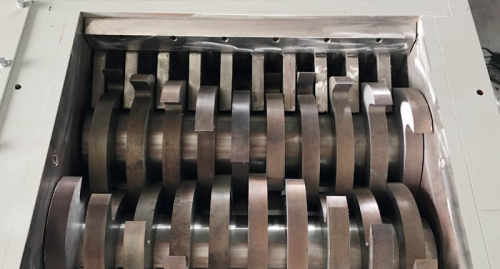

Oct 14, · A single roll crusher has a roll assembly consisting of a roll shaft and a fabricated roll shell with integral fixed teeth. In the single roll crusher, three different methods of reduction occur: impact, shear and compression. Entering the crusher through the feed hopper, the feed material is struck by the teeth of the revolving roll.

Learn MoreRoll Crushers - HAZEMAG

Roll Crusher | HRC. For the industrial beneficiation of raw materials, energy-efficient roll crushers, with high throughput rates, are becoming increasingly important from an economic and ecological point of view.

Learn MoreRoll Crushers - Top 2022 Models - 911 Metallurgist

It is generally considered that Roll Crushers are specially adapted for intermediate crushing, taking a product from rock- breakers with a maximum diameter of

Learn MorePDF) The Influence of the Structure of Double Toothed Roller

The best test scheme and the order of three influencing factors are obtained, which provides the basis for the design of the double toothed roller crusher.

Learn MoreRoll Crusher Drawing | Crusher Mills, Cone Crusher, Jaw Crushers

Double Roll Crusher Double Roll Crusher is for crushing of coal, coke, cinter, moderately hard rock, ore, chalk, etc. Single roll crushers Crusher - Wikipedia, the free encyclopedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.

Learn MoreHow To Design Roll Crusher.pdf [vlr088qdgjlz]

DESIGN CONSIDERATION: Roll Crusher Type: Double Roll Crusher Material to be crushed: Bituminous coal, Broken Maximum Feed Size: 2 3/8 in. Distance Between rolls: 1 ½ in.

Learn MoreDesign, Fabrication and Testing of a Double Roll Crusher

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work. The throughput capacity of the machine was

Learn MoreSampling Sizers/Roll Crushers | McLanahan

In addition to being backed by this experience, Sample Double Roll Crushers and Sizers offer a simplified design and long-term, reliable operation with minimal maintenance requirements. Low profile designs (and minimal footprint in the case of sizers) make for

Learn More

Leave A Reply