High-Speed Gyratory Crushing --> Fine Cone Crushers

This 10″ reduction crusher, with its 40″ head, compares closely, in this respect, with the 20″ standard crusher, which has a 38″ head. Using straight-face concaves, the permissible minimum open side settings are 1.5″ for the former, and 3.5″ for the latter. With non-choking concaves these settings are, respectively, 1 1/8″ and 2 1/4″.

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower

Learn MoreGyratory Cone Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher shape of two cones are steep, and can be fixed upright truncated cone is the cone, fixed cone is inverted truncated cone, which is mainly to increase - Fuller-Traylor gyratory crushers

Learn More1600 TPH GYRATORY CONE CRUSHER WORKING #short #shorts #viral

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

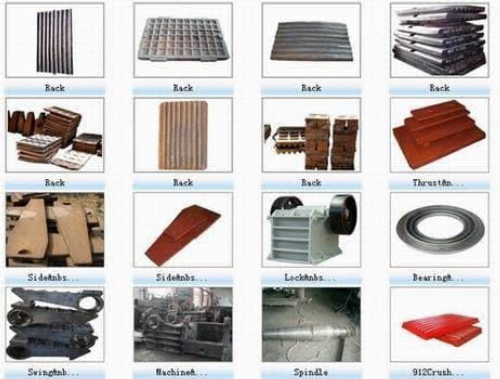

Learn Moregyratory crusher mantle | spare copper-alloy parts for crusher crusher

A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves. As the mantle gyrates within the crushing chamber, progressively approaching, and receding from, each element of the cone shaped inner surface, it creates compressive force, which fractures the

Learn MoreCrushing, screening, feeding and plant solutions

equipment, whether it is our gyratory or cone crushers, Ludowici screens or feeders, has continuously withstood the harshest requirements found in the

Learn MoreGyratory Crusher HOW IT WORK | Crusher Mills, Cone Crusher, Jaw Crushers

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Crusher & Grinder « Novamining What is a Gyratory Crusher and how it works? The gyratory crusher consists essentially of a long spindle, carrying a hard steel conical grinding element,

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

Jaw Gyratory Crusher Pro – the next generation of thyssenkrupp´s unique bestseller for crushing is now available. The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial

Learn MoreGyratory Crushers - SolidsWiki

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory cone crushers are

Learn MoreWhat is a Gyratory Crusher | Quarrying & Aggregates

The structure of the gyratory crusher is the same as that of the single-cylinder hydraulic cone crusher. It is difficult to repair and maintain, and the repair cost and the cost of wear parts are high. Application of gyratory crusher. The equipment investment operator is a non-ferrous metal mining enterprise focusing on mining molybdenum

Learn MoreCone Crushers | McLanahan

Features & Benefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Learn More

Leave A Reply