What is a Gyratory Crusher | Quarrying & Aggregates

The crushing process of the gyratory crusher is to rotate one circle along the annular crushing cavity, and it can work continuously at 360°, while the main shaft of the jaw crusher rotates only 135° once, so the production efficiency of the gyratory crusher is that of a jaw crusher. 2-3 times as high as the production efficiency.

Learn MoreGyratory Crusher Parts | Crusher Parts - Matec solutions

Gyratory Crusher Parts Features: 1, Dimension accuracy and Compatibility is guaranteed; 2, Customized dimension and material service is available; 3, Reliable performance is assured by good quality; 4, Superior wear resistance property optimized for longer service life. 5, Brand Supported:

Learn MoreCSP Gyratory Crusher Wear Parts - Cast Steel Products

Using our proprietary manganese steel alloy CSP Gyratory Crusher wear parts are continually improved with upgrades and developments. Our CSP Gyratory

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive run-on-mine (ROM) rocks directly from the mines.

Learn Moregyratory crusher | HP300 ELBOW FF5163-0808S

gyratory crusher manufacturer,suppliers,primary gyratory gyratory crusher. yjmt gyratory crushers are real state of the art technology and have been designed for high throughputs and economical good cone crusher spare wearing plate manufacturer with iso approval HP300 ELBOW ADAPTER GG306-NP04-02, (MALE 7/16 cone crusher concave install r136

Learn MoreCSP Gyratory Crusher Wear Parts

We offer high-quality replacement gyratory crusher wear parts for: , , and ThyssenKrupp and other leading manufacturers. FEATURES & BENEFITS Proprietary manganese steel alloy for reduced maintenance and increased uptime. Decreased downtimes and increased cost savings. Better fit for quick and easy replacement.

Learn MoreGyratory Crushers - Mineral Processing & Metallurgy

Gyratory crusher advanced design includes the placing of circumferential ribs around the top and bottom shells. These integrally cast reinforcing rings prevent distortion provide the rigidity necessary to maintain true alignment of running parts. 30-55 MAINSHAFT ASSEMBLY ready for shipment SPIDER DESIGNED FOR MAXIMUM RIGIDITY AND STABILITY

Learn MoreGyratory Crusher Services I Service - thyssenkrupp Mining Technologies

Gyratory Crusher Services Patrik Handel 2022-04-27T13:06:08+02:00 thyssenkrupp Gyratory Crusher Services for optimized Operation & Maintenance Get the best out of your gyratory crushers - with services from thyssenkrupp which combine decades of expertise with state-of-the-art technology.

Learn MorePrimary Gyratory Crusher Parts - CMS Cepcor

At CMS Cepcor® we manufacture reliable and high-quality replacement parts for primary gyratory crushers which are shipped worldwide. Contact us today.

Learn MoreGyratory Crusher Parts - 911 Metallurgist

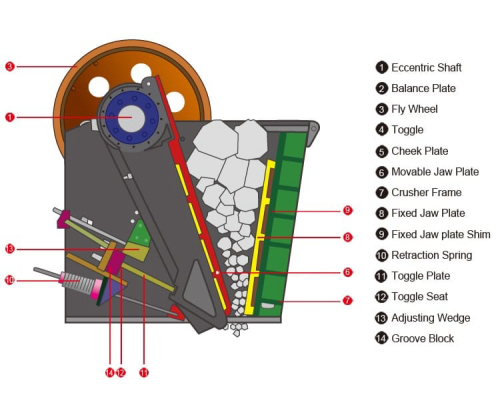

Gyratory Crusher Parts ; Eccentric Support Plate, Pinionshaft Bearings ; Upper Hydroset Bushing, Pinionshaft Seals ; Lower Hydroset Bushing, Spacer.

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

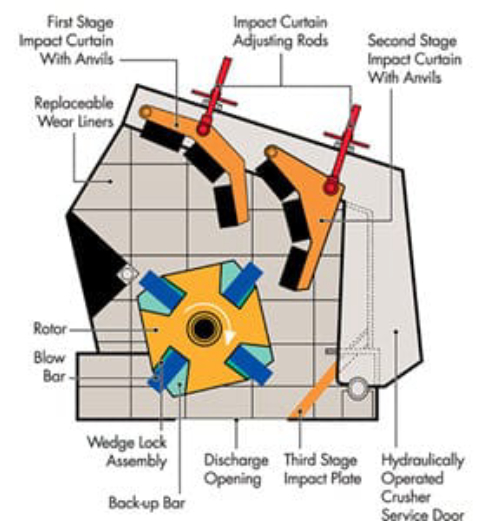

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

Leave A Reply