Hydraulic Cone Crusher - AF Minerals Equipment

The hydraulically adjusted CC and CC-S cone crushers manufactured by AF Minerals Equipment are characterized by robust design and high performance. In combination with the CLP crushing chambers, high-motor powers give these crushers capacities, which in most cases are comparable with those of other larger crushers.

Learn MoreWhat Are Cone Crushers? - Engineering World

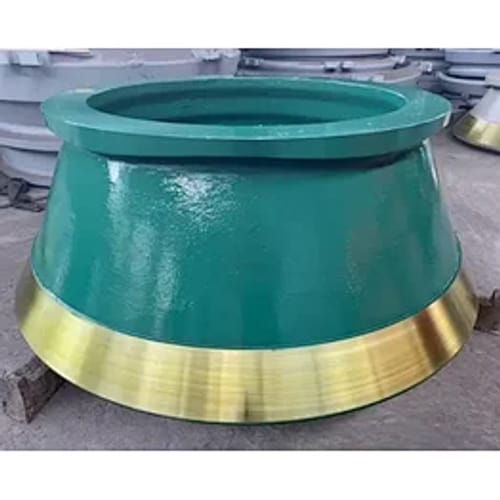

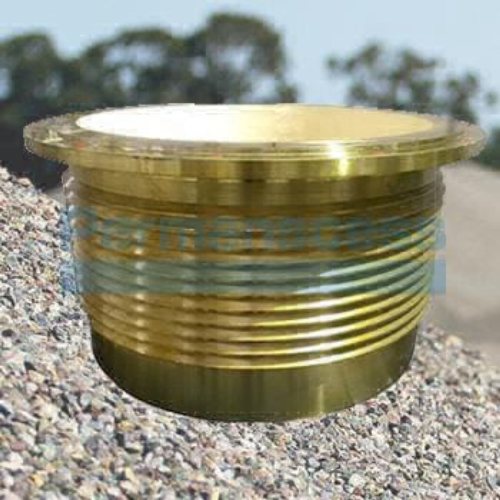

Cone crusher is a type of machine widely used in urban construction, which basically reduces the size of the material with the help of compression, squeezing or breaking down between stationery and moving piece of steel. The size of the output material is controlled by managing the gap between the moving and the stationery steel parts at the

Learn MoreHow to Size a Cone Crusher Motor - Mineral Processing & Metallurgy

Feed size is 3¼-in. Product size is 15/16-in. Ratio of reduction is 3¼-in. divided by 15/16-in. or 3.45. Impact strength is 15. 15/16-in. is found in Graph No. 2. Follow up to line 15, and across to 1.25 hp-hr per ton. Using Graph , the reduction ratio of 3.45 has a correction factor of 0.76. Limestone weighs 100 lb per cu ft, broken.

Learn MoreCone Crushers | Moore Watson Ltd

The Cone Crushers can easily meet different production needs by selecting crushing chambers and different eccentricities. The MP Cone Crusher is an excellent

Learn More5 Types of Cone Crushers Comparison - JXSC Machine

Contact Now +86-13879771862. Published time:09 October 2019. Cone crusher is one of the most widely used mining equipment. This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one. JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit.

Learn MoreCone Crushers Market Share, Size and Forecast 2022-2027

A cone crusher is a mechanical device used to reduce the size of large rocks. It is widely used in the construction and mining industries to crush hard and abrasive materials, such as river gravel, basalt, granite, iron, chrome, magnesite, and copper ores. 5 Global Cone Crushers Market 5.1 Market Overview 5.2 Market Performance 5.3 Impact

Learn MorePDF HP series cone crushers Wear parts application guidePDF

HP cone crusher instruction manual. Before changing the speed of the crusher, consult product support for further information. 6. Check the cavity in use. • Based on feed size • Based on required end product size which determines the required setting range • Check the crushing reduction ratio 7. Check the wear profile of the liners: a

Learn MoreAstec Kodiak® Cone Crushers - Astec - Default

A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. The Kodiak ® cone crusher meets coarse and fine crushing application requirements and offers on-the-fly adjustability for easy operation. 7:41.

Learn MoreMobile cone crushers | for recrushing | Kleemann

Mobile cone crushers ; Drive concept, Diesel-direct ; Feed capacity up to approx. 270 t/h ; Crusher system size, 970 mm

Learn MoreCone Crusher Explained - saVRee

As the feed moves towards the drive end of the cone crusher, its size decreases (due to the crushing action), and ever smaller pieces move towards the drive

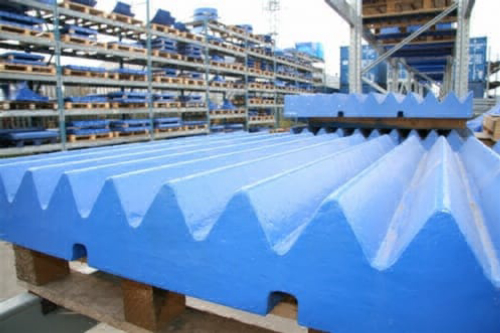

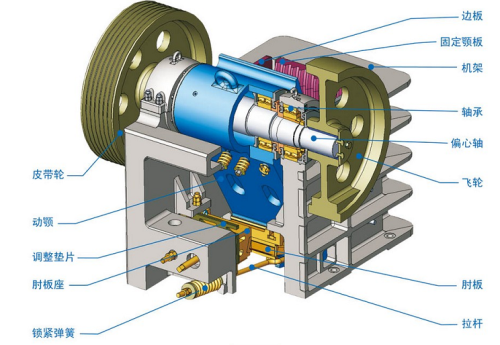

Learn MoreJaw Crushers - high quality and reliability from RETSCH

The jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600.

Learn More

Leave A Reply