Primary and Secondary Crushing for Stone Crusher Plant

In the stone crusher plant, primary crusher and secondary crusher are usually applied together in order to get perfect crushing effects. +86-371-63699132 [email protected] Skype:

Learn MorePrimary Impact Crushers - MEKA Crushing & Screening Plants

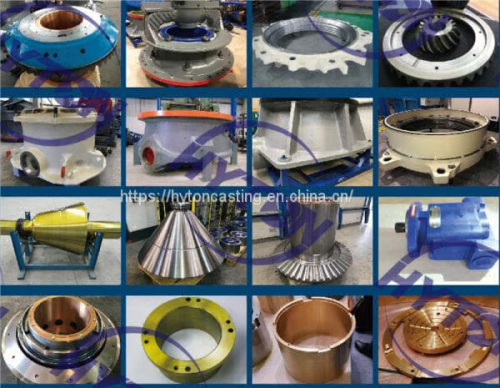

MEKA’s primary impact crusher liners are designed to be interchangeable, meaning less inventory space is needed and reduced inventory cost for our customers. The blow bars are also designed to be reversible for the same reasons. EASY MAINTENANCE FOR HIGH PERFORMANCE. Crusher productivity is directly related to maintenance and safety.

Learn MoreSecondary Crushing Equipment - Mineral Processing & Metallurgy

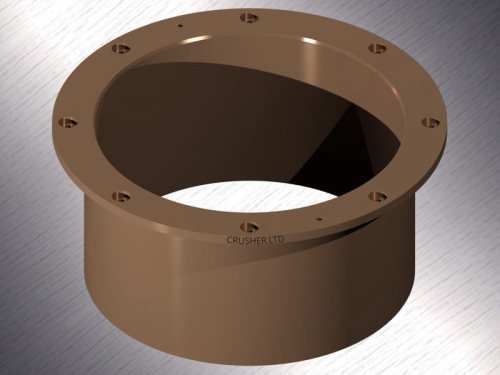

Three factors are of prime importance in selecting the size and type of the secondary crusher, or crushers: capacity; size of feed, size of product. You add to these the item of product characteristic, which embraces shape characteristic, and gradation. These are not always important, but they are sometimes very much so. Capacity of Secondary Stage

Learn Morecrusher installation in primary sequence secondary and tertiary

Crusher installation in primary sequence Primary stone crusher,secondary crusher,tertiary crusher pew jaw crusher this series of jaw crusher crushing compression strength not higher than 280mpa ore, rock, slag, etc, were broken. Obtener precio. Aggregate Crusher Plant Machine DM 55 Mobile Tertiary .

Learn MorePrimary And Secondary Crushing - Crusher Mills

Primary and Secondary Crusher Hammers - Wear Parts + Steel Our H79 alloy steel hammers provide reliable, consistent service for secondary and primary crushers. H79 is a high strength alloy steel with a hardness of 477-512 HB. primary secondary and tertiary diagrams - Crusher South Africa primary crust secondary and tertiary.

Learn MoreImpact Crusher & Cement Crusher Manufacturer - Stedman Machine

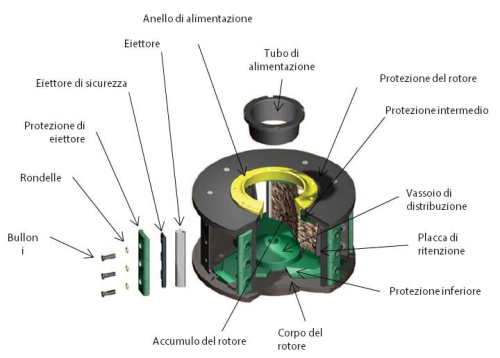

What is an Impact Crusher? An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of Impact Crushers:

Learn MoreCrushers - All crusher types for your reduction needs

Outotec crushers are fit for aggregates production, Horizontal shaft impact (HSI) crushers are used in primary, secondary or tertiary crushing

Learn MoreCrusher - an overview | ScienceDirect Topics

The secondary crusher is mainly used to reclaim the primary crusher product. The crushed material, which is around 15 cm in diameter obtained from the ore

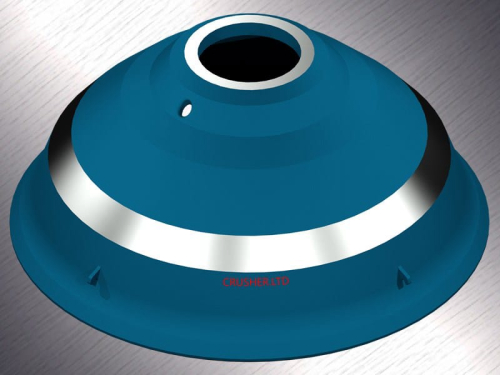

Learn Moreallis chalmers primary girotry crusher specifications

1000 TPH Primary Gyratory Crushing Plant Item #1 - Fuller-Traylor Model 42-70 Type TCB Gyratory Crusher with cast steel two piece mainframe, 400 - 4,000 volt electric motor, direct shaft drive, hydraulic $145,000.

Learn MorePrimary And Secondary Crushing Crushers

Crushers and Their Types IspatGuru Apr 03, The primary crusher receives material directly from run of mine ROM after blasting and produces the first reduction in size. The output of the primary crusher is fed to a secondary crusher, which further reduces the

Learn Moredifference in primary and secondary crushing

Primary crushing brings runofmine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below dry crushing includes work on ore as mined, which may be somewhat moist when delivered. it is succeeded by comminution in water, arbitrarily called grinding.

Learn More

Leave A Reply