What is a Gyratory Crusher | Quarrying & Aggregates

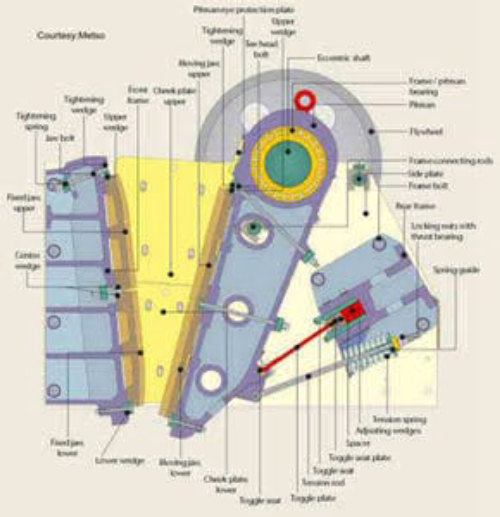

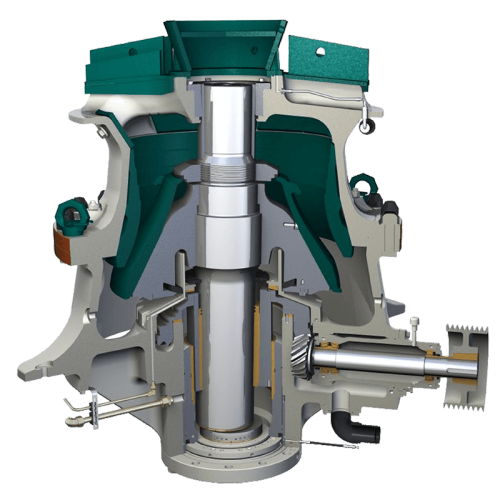

It is difficult to repair and maintain, and the repair cost and the cost of wear parts are high. The high fuselage of the gyratory crusher results in high infrastructure costs such as foundations and workshops. Generally, aerial cranes are required to facilitate maintenance. Application of

Learn MoreCrusher maintenance services

Close examination and good maintenance of your crusher protects your plant's overall productivity. By acting fast, you can avoid poor performance, stoppages and costly repairs. Our regular crusher inspections and ongoing technical support ensure your equipment keeps operating at maximum efficiency.. In addition to these comprehensive inspections, our crusher maintenance services include

Learn MoreGyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn MoreGyratory Crusher Failure Modes | AMP Maintenance Forums

Anyway, I was wondering if anyone can assist with failure modes of Gyratory Crushers. The model we have on site is a KB 63 - 89.

Learn MoreGyratory crusher upgrades - Outotec

Go from MK I to MK nXt with our Superior primary gyratory crushers upgrades. Mix and match to suit your goals: better production, reliability & maintenance.

Learn MoreHOPPER CLEANING OF GYRATORY CONE CRUSHER 4 SCHEDULED

9/1/2022 · HOPPER CLEANING OF GYRATORY CONE CRUSHER FOR SCHEDULED MAINTENANCE OF RING SEALINGPlease subscribe#technical_info_fe2o3#crusher#crushing#miningengine

Learn MoreGyratory Crusher

PERFORMANCE why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Learn MoreAvoid Unplanned Downtime: 5 Crusher Maintenance Best

To prevent machine failure, Schmidt offers tips on horizontal shaft impact (HSI) crushers and cone crushers. Perform Daily Visual Inspections.

Learn Mores new Digital-Enabled TSUV Gyratory Crusher

The unique top-service design prioritises safety, easy maintenance and efficient crushing performance. Unlike other gyratory crushers, which

Learn MoreGyratory Crusher Maintenance

Gyratory Crusher Main Shaft. the gyratory crusher ts is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. it is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience. thyssenkrupp gyratory crushers represent today's state-of-the-art. They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs. Maintenance friendly design

Learn More

Leave A Reply