Cone Crusher Lubrication Oil Manufacture and Cone Crusher Lubrication

Cone Crusher Lubrication Oil - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Iron Ore Slag Rod Mill Crusher Machine.

Learn MoreCone Crushers Support | McLanahan

Cone Crusher Maintenance. How often should I change the lubrication oil? For a new crusher, change the lubrication oil after 100 hours of operation.

Learn MoreCone crusher maintenance critical to optimum output - Quarry

04/04/ · USE THE CORRECT OIL. The type and condition of your lubrication oil is critical to successful operation of your cone crusher. Crushing with worn out oil or oil of the wrong

Learn MoreReasons for the increase in lubricating oil temperature of cone crusher

11/09/ · The lubricating oil in the cone crusher has been used for too long. Under normal circumstances, the lubricating oil replacement cycle is 2000h. If it exceeds 2000h, the lubricating oil viscosity and other indicators will be seriously reduced. Too many impurities in the oil will cause the quality of lubrication to decrease.

Learn MoreGlobal Mining Review - Lubricants for Compression Crushers

Like gyratory crushers, cone crushers utilise a remote reservoir system to provide filtered and temperature adjusted oil to the step bearing,

Learn MoreMobile Crushers] LT550GPF

Other Housing(s) - Cone Crusher Lubrication Oil. Service Refill Capacity: 350 Litres. image description. CASTROL ALPHA SP 150. A high quality, API GL

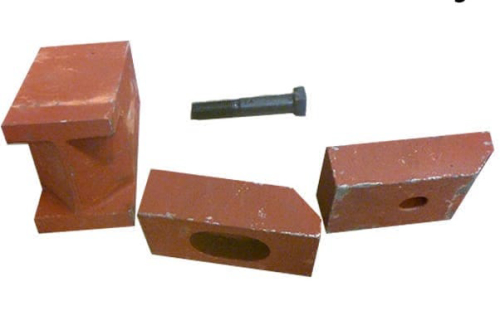

Learn MoreCone Crusher Parts - Mineral Processing & Metallurgy

19/02/ · The lubricant is sealed in with a garter type oil seal. Bearings can be lubricated from outside the topshell on the 51, 60 and 84-in. crushers through oil holes in spider caps of the four smaller sizes. Cone Crusher MAINSHAFT. The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit.

Learn MoreCrusher Lubricant™ ISO 150 - Products - Gear Lubricants - D-A Lubricant

Crusher Lubricant™ ISO 150. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is specially formulated to be compatible with bronze and brass bushings and bearings.

Learn MoreNotes of Cone Crusher Lubrication System

1) The lubricating oil goes into the cone crusher by two paths. One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole lubricating big and small gear, and then the oil will return from the bottom oil returning

Learn MoreLubricating crushing machines in quarries - Rock to Road

The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. For crusher systems that use oil lubrication for example, contamination of

Learn MoreMinerals Cone Crusher 1003894081 Lube Oil Filter

Find many great new & used options and get the best deals for Minerals Cone Crusher 1003894081 Lube Oil Filter Element at the best online prices at

Learn More

Leave A Reply