The basics of crushing : Pit & Quarry

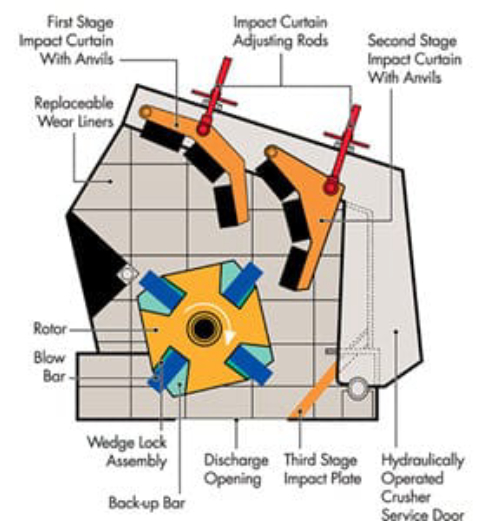

Impact crushing quick facts 1. The faster the speed, the finer the gradation. 2. Setting has some effect on gradation and throughput, but speed is by far the most important factor. 3. Rotor penetration is critical for best performance. 4. Double the speed equals four times the wear. Crushing efficiency

Learn Morethree stage crushing opcircuit to closed circuit

ROM ore is crushed at a rate of up to 2.5Mtpa in a three stage crushing circuit incorporating a primary jaw crusher operating in open circuit and a secondary and tertiary cone crushers operating in closed circuit with a double deck banana screen. Crushing circuit product, at a nominal size of 12mm is conveyed to the grinding circuit via the

Learn MoreFlow Chart Of Three Stage Agreegate Crushing Plant Stone Crusher

The second one consisted of a UG2 ore obtained from a crushing plant feeding a rod and a ball mill.Flow sheet options Today the standard process for the comminution of platinum ores is two-stage milling and flotation (FigureThe float tails are fed to the secondary ball mill operating in open circuit. flow sheet of a two stage crushing plant

Learn Morethree stage crushing circut

Two Stage Crushing Circuit three stage crushing circut Machinery is one of the biggest manufacturers in Flowsheet of a two stage crushing plant open circuit Read More Harrington Investments We can invest for a better world Harrington Investments has been a leader in Socially Responsible Investing and Shareholder Advocacy since 1982

Learn Morethree stage crushing circut

Crushing and Grinding Circuit Design 2018-2-20 • three stage crush, ball mill e.g. (Three Mile Hill). • two stage crush, ball mill, e.g. Pajingo. • a crushing circuit including high pressure grinding rolls (HPGR) at Argyle Diamond Mine. Recent feasibility studies for the

Learn MoreHow to Recover Iron from Magnetite: 4 Methods and Stages

The crushing stage is the pretreatment of magnetite. The crushing process of magnetite often adopts a continuous flow of two-stage and one closed-circuit crushing. 1 The raw magnetite ore is sent to the coarse crusher (jaw crusher) by the vibrating feeder, and then sent to the fine crusher (cone crusher or hammer crusher). 2 After fine crushing

Learn More2 Stage or 3 Stage Crushing? – Trimax Machinery – Simply Better Crushers

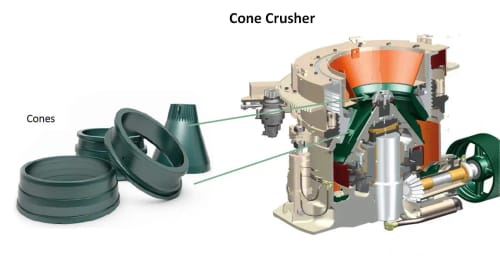

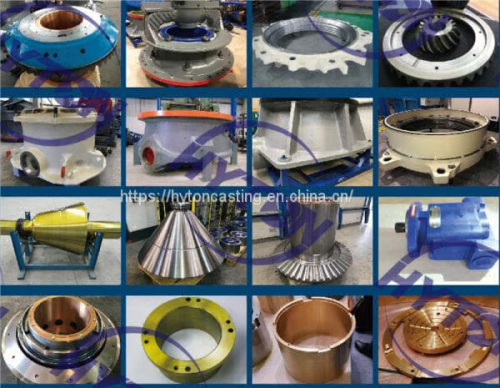

7/23 · That’s another common question that may be asked. That question is easier to answer. 2 stage crushing involves just 2 crushers in a crushing plant, i,e, a primary crusher and a secondary crusher. This is usually, although not always, a jaw crusher and a cone crusher. 3 stage crushing just means that there are 3 crushers within the crushing plant.

Learn MoreCrushing Circuit - an overview | ScienceDirect Topics

1.2.2.1.2.1 Liberation Size. The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are

Learn MoreCrushing Plant Design and Layout Considerations - JXSC Mine

1 Considerations of stone crusher plant design. The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1) supply the most reasonable ore feeding size for rod grinding, ball milling, or provide qualified grinding medium for autogenous

Learn MorePDF Selection oof Comminution Circuits for Improved EfficiencyPDF

circuit (crushing, stockpiling and grinding) representing 35% and 50% of plant capital cost for the 1 Mt/a and 20 Mt/a plants, respectively. Comminution costs include power, grinding media and maintenance materials. These costs represent 30% of costs for the 1 Mt/a plant and over 50% of costs for the 20 Mt/a plant.

Learn MoreRevamp for three-stage hard rock crushing plant - Quarry

3/19 · From there, it is conveyed to a secondary G90 cone crusher where it is crushed to a size of 50mm in closed circuit with a screen. The product from the secondary crusher will already meet product standards, so the 25-50mm fraction can be screened out and sent to product stockpiles for use as railway ballast, drainage systems or other products.

Learn More

Leave A Reply