Wear And Selection Of Jaw Crusher Jaw Plate – Jaw Crusher

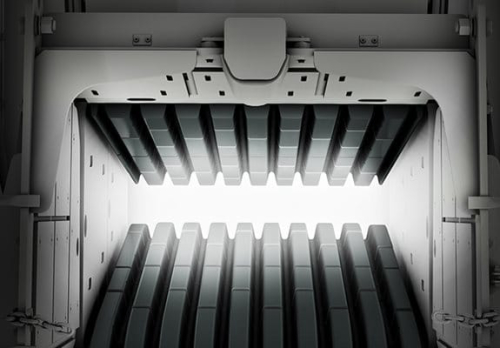

The wear of the Jaw Crusher Jaw Plate is a chisel wear. The tooth plate material is the standard high manganese steel by water treatment. Under the scanning electron microscope to observe the tooth plate grinding surface can be seen, the tooth plate surface is squeezed into the convex part of the material, and then by the abrasive puff to form a pressure tongue grinding, grinding

Learn MorePDF Primary size reduction with Jaw Crushers - McCronePDF

Jaw Crusher BB 300 8-9 - Selection guide / technical data 10 - Breaking jaws 11 - Order data 12 Milling - Jaw Crushers - Rotor Mills - Cutting Mills RETSCH Jaw Crushers are used for the rapid, gentle crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials

Learn MoreCrushers Selection Guide: Types, Features, Applications

Feed size, material, and hardness must be considered. · Output size ranges. · Crushers accept dry or wet input, or both. · Crushers are feed in batches or

Learn MoreJaw Resources | MPS

Swing Jaw. Replaceable die plate attached to the pitman. Bolt on wear plates designed to protect crusher frame. Some designs of jaw crushers require wedges to ensure that the jaw plates are held firmly in position. These are also a wear part that can be replaced when worn down.

Learn MoreChoosing the right primary crusher for your aggregate

Jaw crushers are workhorse crushers and the most commonly used. They're fit for abrasive material as well but are far more portable than gyratory crushers and

Learn MoreSelection Of The Material Of Jaw Crusher Plate – Jaw Crusher

Selection Of The Material Of Jaw Crusher Plate The impact of jaw plate wearable reason is mainly wear-resistant material hardness and toughness. ① material is too hard, the material extrusion depth is shallow, the material deformation is small, the material for material short-range sliding chisel cut is also small;

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force ... - Hindawi

The force transmission characteristics can be used as criteria for the comparison of different jaw crusher mechanism designs in order to select the most

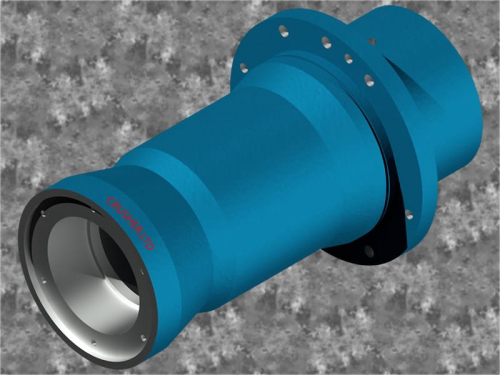

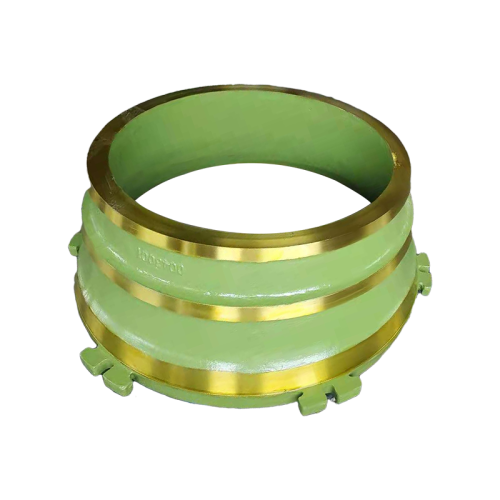

Learn MoreVertical Shaft Bearing Selection | Crusher Mills, Cone Crusher, Jaw

New Vertical Shaft Wheel Horse. including but not limited to a great selection of Bow Sights. vertical shaft bearings, vertical shaft diesel, vertical shaft . 2. Selection of Bearings . (495)-228-06-21, n Zdk (495) 223-3071. Selection of Bearing Type Refer to pages, 18, 39~53 Refer to pages, 14~17, 18, 29~35 .

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Learn MoreJaw Crushers - Astec

Jaw Crushers Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability.

Learn MoreChoosing the right crusher - Buying Guides DirectIndustry

Read our buying guides and make the right choice The jaw crusher is a machine for crushing rocks and other hard and abrasive materials, such as granite,

Learn More

Leave A Reply