Crusher Duty Motors

Baldor•Reliance Crusher Duty motors are designed for Belt-driven rock crushers, pellet mills, and other applications requiring motors rated for severe duty service and high starting torques.

Learn MoreCrusher, Crushing plant - All industrial manufacturers

stationary compact for mineral material. Weight: 990, 1,380 kg. Motor power: 7.5, 11 kW. Mini electric jaw crusher CR series is ideal for the recycling of aggregates from small demolitions, excavations, natural stones, rock, tiles, scraps of marble, reinforced concrete.

Learn MoreHillsboro, Oregon - Wikipedia

Hillsboro (/ ˈ h ɪ l z b ər oʊ / HILZ-burr-oh) is the fifth-largest city in the U.S. state of Oregon and is the county seat of Washington County. Situated in the Tualatin Valley on the west side of the Portland metropolitan area, the city hosts many high-technology companies, such as Intel, locally known as the Silicon Forest.At the census, the city's population was 106,447.

Learn MoreUSD875795S1 - Vertical shaft impact crusher rotor - Google Patents

crusher rotor rotor Prior art date 2016-06-29 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as

Learn MoreRQI Inc Impact Crusher Replacement Parts - rotors

RQI designs and manufactures impact crusher rotors of the highest quality and advanced designs. RQI's rotors beat the OEM spare parts pricing, yet meet or exceed OEM specifications. RQI's unique Bar & Cap Systems are available for most models of primary impact crushers and will increase crusher productivity while keeping the operating cost low.

Learn MoreVSI Rotors and Wear Parts - KoneCarbide

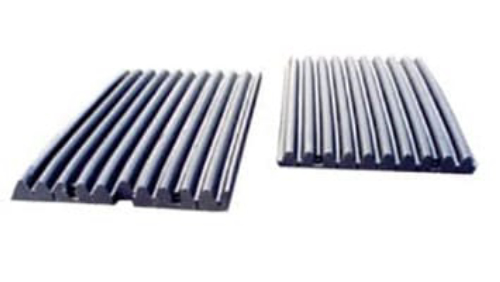

The rotor is the most crucial part of a VSI crusher. KoneCarbide supplies top-quality VSI rotors and wear parts for world well-known brands, such as and , at a competitive

Learn More4 Types of Stone Crushers' Maintenance and Efficient Improvement

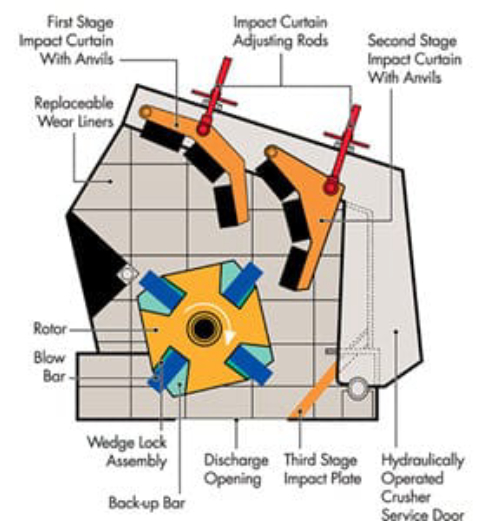

Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces. Then the crushed material would be thrown by hammers towards, which makes another crushing process "stone to stone".

Learn MoreImpact Crusher - an overview | ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

Learn MoreHammer Crusher Rotor, Rotor for Hammer Crusher, Crusher Rotor for Sale

Crusher rotor is the key component of crusher. After long time use, the hammer pin is likely to be out of shape, and the hammer plate and crusher hammers are likely to break. All these problems have been completely solved as manufactures optimized crusher rotor.

Learn MoreHammer Crusher Rotor > Crusher Parts > Products

Hammer crusher rotor is the key component of hammer crusher. After long time using, the hammer pin is easily to be out of shape,also the plate and crusher hammers are likely to break. manufactures the optimized crusher rotor, and solves all these problems completely. Benefit Advantages:

Learn MoreRotor Centrifugal Crusher Market Size In 2022 : Corporate Strategy, Top

Rotor Centrifugal Crusher Market Research Report is spread across 94 Pages and provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

Learn More

Leave A Reply